Piezoelectric Film

Piezoelectric film sensors have become one of the fastest-growing technologies in the global sensor market. There have been numerous instances where the piezoelectric element was considered for the sensor solution. Since the discovery of piezoelectric polymers in the last two decades, the technology has advanced significantly and is being adopted on a larger scale. In this application note, the development of piezoelectric film polymer technology, its properties, and sensor design are discussed in detail.

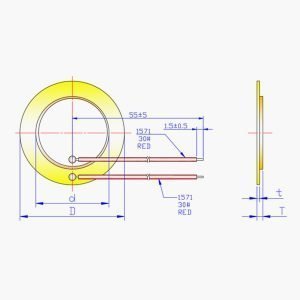

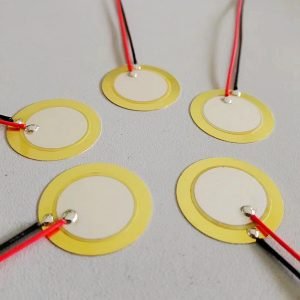

The piezoelectric element 3 electrodes, diameter is 27mm, frequency is 3.8KHz, made of brass base, and piezo ceramic disc.

The difference between a separately excited piezo element and self-drive piezo element;

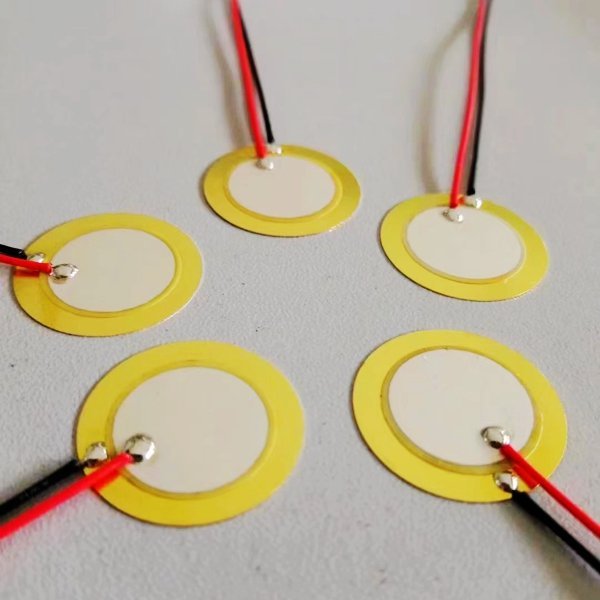

First of all, from the appearance point of view: excited piezoelectric element, that is, two-electrodes, which is processed by a substrate (copper sheet/steel sheet/iron sheet/alloy sheet) plus a piezoelectric ceramic sheet, and only the two contact points can be welded with positive and negative lines, as shown in the figure below:

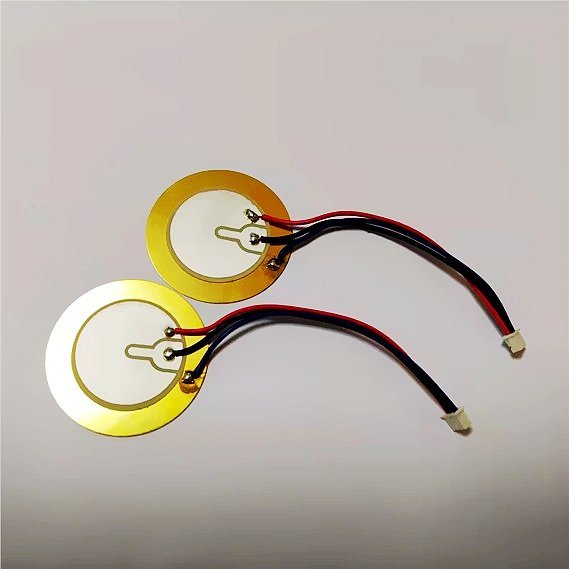

Self-drive piezo element, that is, three electrodes, is made of a substrate (copper sheet/steel sheet/iron sheet/alloy sheet) plus a piezoelectric ceramic sheet with feedback electrode. There are three the contact point, you can weld three positive and negative wires, one of which is the feedback electrode, as shown in the figure below:

The important difference lies in the principle and application. The piezoelectric ceramic film with feedback electrodes is generally used in the active piezoelectric film. The frequency of the sounding chip is fed back to one end of the triode, generating a resonance frequency point.

On the contrary, the externally excited buzzer has no feedback effect, and can only rely on the IC signal or the given frequency signal of the inductance circuit to match the frequency of the sound.

Hot Tags: Piezoelectric film, Manufacturer, Price, For Sale

Reviews

There are no reviews yet.