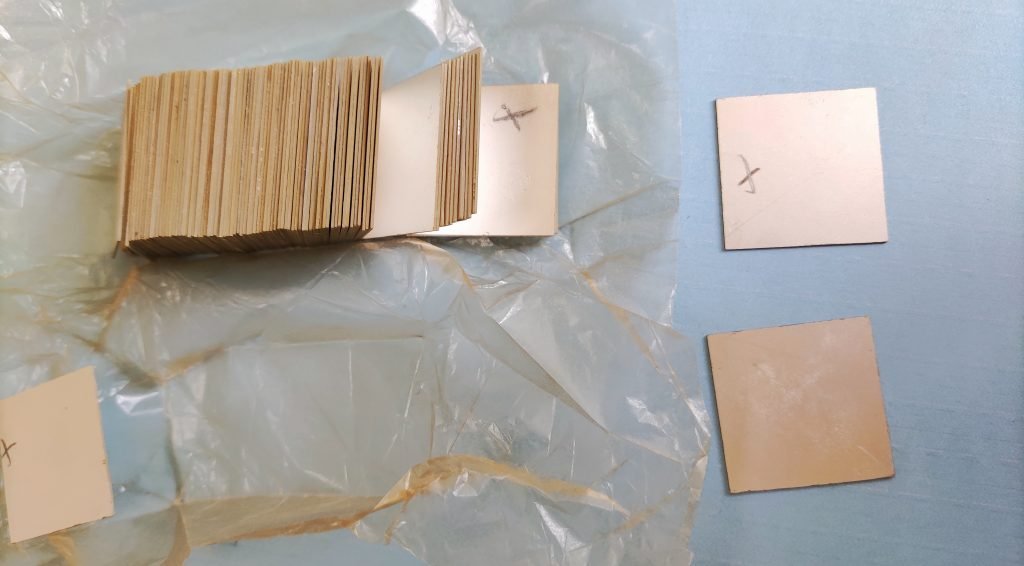

Piezo Plate Customized

Piezo Plate Process

batching, In addition to various and damp pre-treatment, weigh all types of raw materials according to the proportions of the formula, paying special attention to a small number of additives in the midst of the huge material.

Mixed grinding fine, The goal is to mix and crush a variety of raw materials in order to create the right conditions for a complete solid-phase reaction and pre-burning. The procedure of dry or wet grinding is commonly used. Small batches can be used for dry grinding, while large batches can be used for high-efficiency mixing ball grinding or airflow crushing.

burn-in, The goal is to mix and crush a variety of raw materials in order to create the right conditions for a complete solid-phase reaction and pre-burning. The procedure of dry or wet grinding is commonly used. Small batches can be used for dry grinding, while large batches can be used for high-efficiency mixing ball grinding or airflow crushing.

Secondary fine grinding, The purpose is to grind the pre-burned piezoelectric ceramic powder to lay a good foundation for the uniform performance of the porcelain.

prill: The goal is to have a high density of good liquid particles in the powder.

Manual methods are less efficient, and spray granulation is the most efficient method currently available.

Adder is added to this process

PZT5 Plate Customized

shaping: The purpose is to make the grain material pressure into the required prefabricated size of the blank

plastic removal: The aim is to remove the adhesive added to the granulation from the blank.

Burning into porcelain: Seal the blank at high temperature into porcelain. This link is quite important.

Appearance processing: Mill the burned product to the desired finished size.

The electrode: Conductive electrodes are placed on the suitable ceramic surface.

Silver layer burning seepage: chemical deposition and vacuum coating are the most common processes.

High-pressure polarization: The electric domain inside the ceramic is arranged directional so that the ceramic has piezoelectric performance.

burn-in test: After the ceramic performance is stable, various indicators are tested to see whether the expected performance requirements are met.

Hot Tags: piezo plate, price, for sale, customized, manufacturer

Reviews

There are no reviews yet.